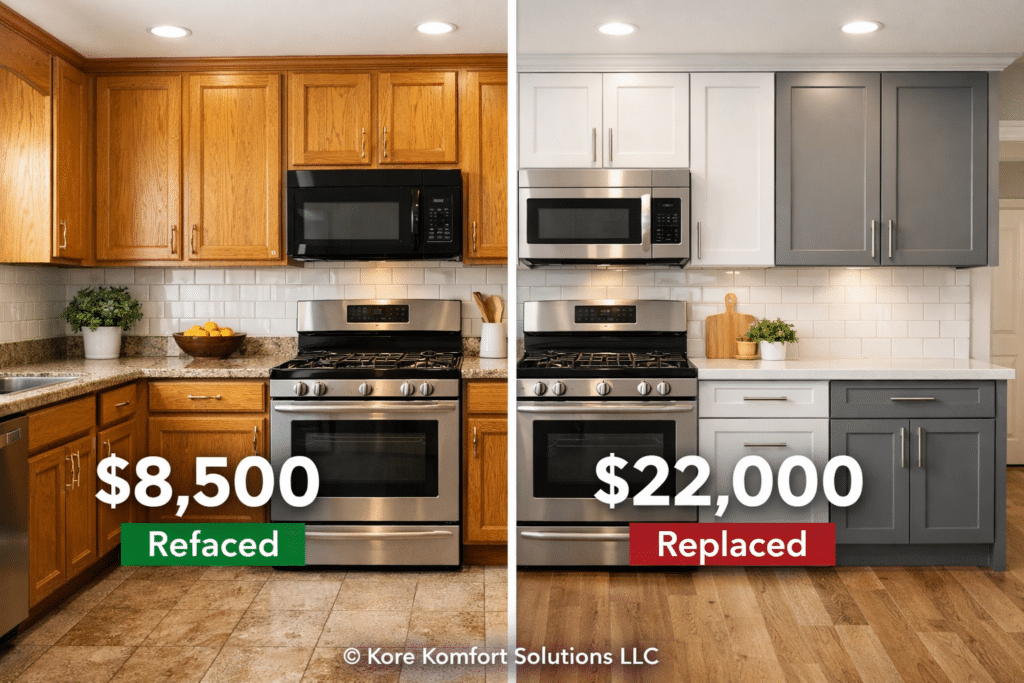

Kitchen cabinets represent one of the most significant investments in any home, often accounting for 30-40% of a complete kitchen remodeling budget. When your cabinets start showing their age, you face a critical decision: should you reface them at $150-$450 per linear foot, or replace them entirely at $400-$1,500 per linear foot?

The financial stakes are substantial. For an average 200-square-foot kitchen with 25 linear feet of cabinetry, you’re looking at $4,000-$12,000 for refacing versus $10,000-$30,000+ for replacement—a difference of $6,000-$18,000 that could fund other home improvements or remain in your savings account.

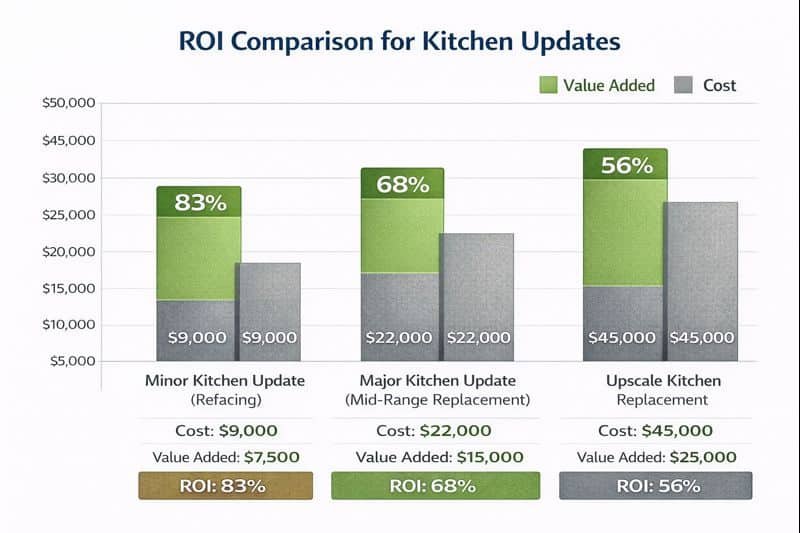

But cost alone doesn’t tell the complete story. Cabinet refacing typically lasts 15-20 years with proper maintenance, while quality replacement cabinets deliver 20-50 years of service depending on construction quality. Return on investment varies too: minor kitchen updates including refacing return an impressive 72-96% of cost at resale, while major replacements typically return only 50-70%.

This comprehensive guide breaks down real costs, hidden expenses, durability expectations, and ROI considerations for both approaches. You’ll learn exactly when each option makes financial sense, what factors affect pricing, and how to make an informed decision that aligns with your specific situation and budget.

Article Navigation

- Understanding the Basics: What Refacing and Replacement Actually Mean

- Cabinet Refacing Cost Breakdown (2026 Pricing)

- Cabinet Replacement Cost Breakdown (2026 Pricing)

- Side-by-Side Cost Comparison by Budget Tier

- Durability and Lifespan: How Long Each Option Lasts

- When Cabinet Refacing Makes Financial Sense

- When Cabinet Replacement Is Necessary

- Hidden Costs Most Homeowners Miss (Add 15-25% to Budget)

- DIY vs. Professional Installation: True Cost Analysis

- Return on Investment: Resale Value and Long-Term Ownership

- Making Your Decision: A Step-by-Step Framework

- Frequently Asked Questions

FTC Disclosure: Kore Komfort Solutions connects homeowners with cabinet manufacturers and dealers. Some links in this article are affiliate links, meaning we may earn a commission if you make a purchase through our network partners. This comes at no additional cost to you and helps us continue providing honest, educational content. We only recommend products and services we believe offer genuine value.

Understanding the Basics: What Refacing and Replacement Actually Mean

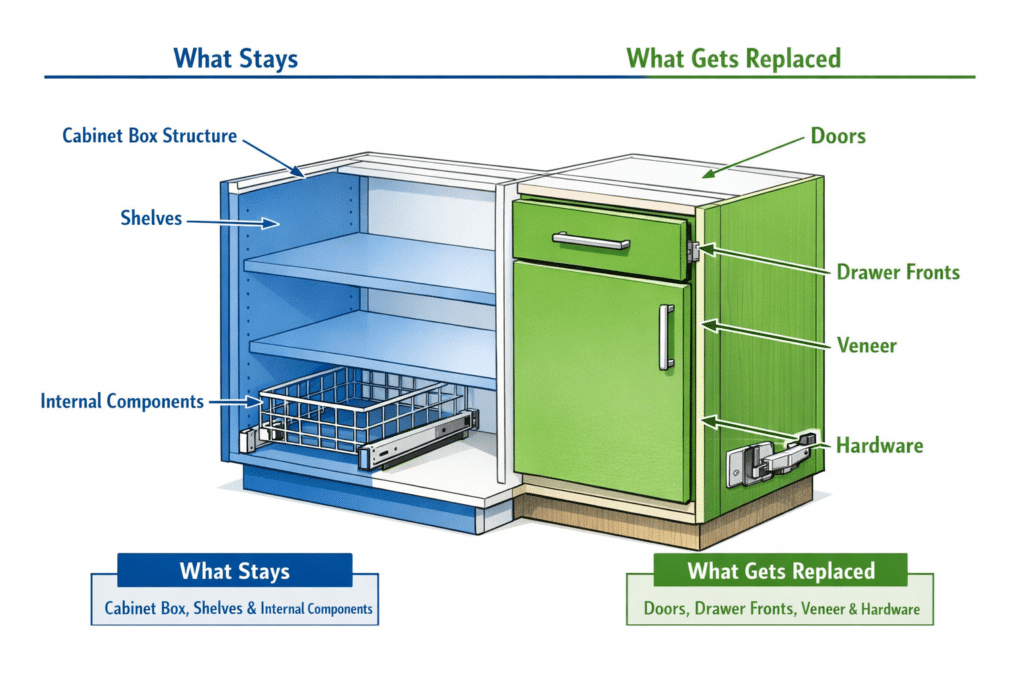

Before comparing costs, you need to understand exactly what separates cabinet refacing from replacement. These terms are often confused or used interchangeably, leading homeowners to make decisions based on incomplete information.

What Is Cabinet Refacing?

Cabinet refacing is a renovation process that preserves your existing cabinet boxes (the structural framework attached to walls and floor) while completely updating all visible surfaces. The process involves removing and replacing cabinet doors and drawer fronts, applying new veneer or laminate to the exterior surfaces of cabinet boxes, installing new hardware including hinges and pulls, and adding or updating moldings and decorative elements.

Think of it as a comprehensive facelift for your cabinets. The bones remain the same, but everything you see gets updated. A professional refacing project transforms your kitchen’s appearance without the structural demolition, plumbing adjustments, or electrical work that replacement requires.

According to the Kitchen Cabinet Manufacturers Association, professional cabinet refacing can completely transform kitchen aesthetics while maintaining existing layouts, making it ideal for homeowners satisfied with their current cabinet configuration but tired of outdated appearances.

Refacing works particularly well for kitchen remodeling projects where budget constraints prevent complete replacement but visual updates are essential. Many homeowners combine refacing with other updates like new countertops or improved lighting to create comprehensive kitchen transformations.

What Is Cabinet Replacement?

Cabinet replacement means removing your existing cabinets entirely—boxes, doors, drawers, shelves, and all supporting components—and installing completely new cabinetry from the ground up. This approach gives you a blank canvas to reconfigure kitchen layout, change cabinet sizes and heights, upgrade to modern organizational features like soft-close mechanisms or pull-out organizers, and select entirely new materials, colors, and construction methods.

Full replacement requires significantly more labor and coordination. Countertops often need removal and reinstallation or replacement entirely. Flooring beneath cabinets may need patching or extension. Walls require repair and repainting after cabinet removal. Electrical outlets and plumbing connections might need relocation if you’re changing the kitchen layout.

This comprehensive approach suits homeowners planning major kitchen renovations, those with structurally compromised cabinets, or anyone seeking to completely redesign their kitchen’s functionality and workflow. The investment is substantially higher, but you gain complete control over every aspect of your cabinetry.

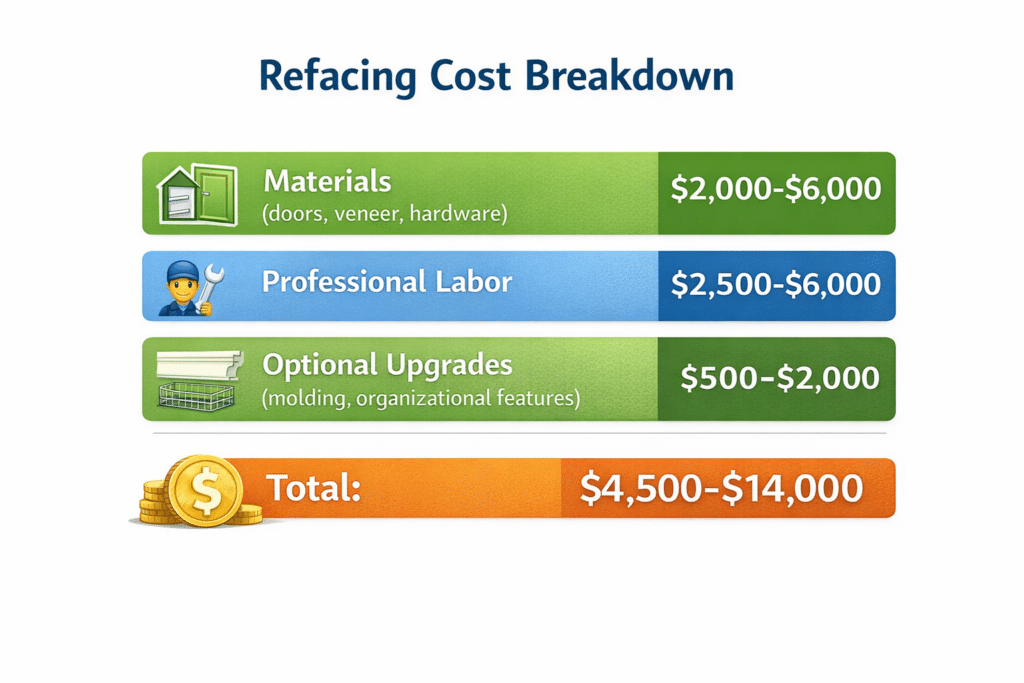

Cabinet Refacing Cost Breakdown (2026 Pricing)

Cabinet refacing costs have increased 8-12% over the past two years due to material cost inflation and labor shortages. Understanding current pricing components helps you budget accurately and identify opportunities for savings.

National Average Costs for 2026

For an average kitchen with 20-25 linear feet of cabinetry, professional cabinet refacing typically costs between $4,500 and $12,000 in 2026. On a per-linear-foot basis, expect to pay $150-$450 per linear foot depending on material selections and project complexity.

These figures represent complete professional installations using quality materials. Budget options using basic laminate veneers and thermofoil doors might come in at $150-$200 per linear foot ($4,000-$6,000 total for average kitchens). Mid-tier refacing with wood veneer and solid wood doors typically runs $225-$325 per linear foot ($6,500-$9,500 total). Premium refacing featuring custom wood doors, crown molding, and specialty finishes can exceed $400-$500 per linear foot ($10,000-$14,000+ total).

Material Cost Components

Door and Drawer Front Replacements: This represents the largest material expense, typically accounting for 40-50% of total costs. The price range varies dramatically by material and construction:

- Thermofoil/Laminate Doors: $25-$75 per door – Budget-friendly option that resists moisture but may show wear over time. Available in limited color selections and styles.

- Wood Veneer Doors: $75-$150 per door – Mid-tier option offering natural wood appearance at moderate cost. Good durability with proper care.

- Solid Wood Doors: $150-$300+ per door – Premium option providing maximum durability, refinishing capability, and authentic wood grain appearance. Price varies by wood species (maple, cherry, oak, etc.).

A typical kitchen requires 12-20 doors and 6-10 drawer fronts, making door selection one of the most impactful budget decisions. For those interested in premium hardware to complement new doors, cabinet hardware sets offer quality options at various price points.

Veneer Materials: The veneer applied to cabinet box exteriors costs $3-$12 per square foot installed. Material choices include:

- Laminate/Thermofoil Veneer: $3-$6 per sq ft – Most affordable, moisture-resistant, available in numerous colors and patterns including wood-grain designs.

- Wood Veneer: $6-$12 per sq ft – Real wood sliced thin and applied to surfaces. Provides authentic appearance and superior durability compared to laminate.

Most kitchens require 100-200 square feet of veneer for complete coverage of all visible cabinet box surfaces, adding $300-$2,400 to material costs depending on selection.

Hardware Components: New hinges, handles, and pulls add $200-$1,000 to total costs depending on quality level and style preferences. Component pricing breaks down as:

- Hinges: European-style hidden hinges cost $3-$8 per hinge. Budget for 30-50 hinges in average kitchens (2-3 per door).

- Handles and Pulls: Range from $2 for basic options to $20+ for designer selections. Most kitchens need 15-25 pulls/handles.

- Soft-Close Mechanisms: Add $5-$12 per door/drawer but dramatically improve functionality and reduce wear. Highly recommended upgrade.

Consider purchasing hardware in bulk for savings. Soft-close hinges offer professional-quality options at competitive prices when buying sets of 20-50 pieces.

Moldings and Trim: Crown molding, light rail, and decorative end panels contribute $200-$1,000 to material costs. These finishing touches are essential for professional appearance but represent an area where budget-conscious homeowners can reduce expenses by selecting simpler profiles or eliminating optional elements.

Professional Labor Costs

Professional installation labor typically accounts for 50-60% of total refacing costs. A complete refacing project requires 20-40 hours of skilled labor, with rates varying from $40-$100 per hour depending on geographic location, contractor experience, and project complexity.

Labor includes comprehensive surface preparation (cleaning, light sanding, minor repairs), veneer application using contact cement and specialized tools, door and drawer installation with precise alignment, hardware installation and adjustment, and final quality inspection with touch-ups.

Experienced installers work more efficiently and deliver superior results. The quality difference between budget contractors and seasoned professionals becomes immediately apparent in veneer application smoothness, door alignment precision, and overall finish quality. Investing in higher-quality labor often proves worthwhile for lasting results.

Regional Cost Variations

Geographic location significantly impacts both material and labor costs. Urban markets and coastal regions typically run 20-40% higher than rural or inland areas. For example:

- Major Metro Areas (NYC, SF, LA, Chicago): $200-$500 per linear foot

- Mid-Size Cities: $175-$400 per linear foot

- Rural/Suburban Areas: $150-$350 per linear foot

Always obtain multiple local quotes for accurate pricing in your specific market.

Cabinet Replacement Cost Breakdown (2026 Pricing)

Full cabinet replacement represents a major investment with pricing that varies dramatically based on cabinet quality tier, kitchen size, and installation complexity. Understanding cost structures helps you identify where money goes and where you might adjust expectations to fit budget constraints.

National Average Costs for 2026

Complete cabinet replacement for an average 10×10 kitchen (approximately 20 linear feet of cabinetry) ranges from $10,000 to $35,000+ in 2026. Breaking this down per linear foot, expect costs of $400-$1,500 per linear foot depending on cabinet quality and features.

The wide price range reflects dramatic quality differences between cabinet types:

- Stock Cabinets: $100-$300 per linear foot for materials only, $250-$500 installed. Available from home improvement retailers in standard sizes and limited finishes.

- Semi-Custom Cabinets: $200-$650 per linear foot materials, $400-$900 installed. Manufacturers like KraftMaid and Thomasville offer more sizes, finishes, and organizational options.

- Custom Cabinets: $500-$1,500+ per linear foot materials, $800-$2,000+ installed. Built to exact specifications by local cabinetmakers using premium materials and construction methods.

Material Cost Components

Cabinet Box Construction: The structural cabinets themselves account for 60-70% of material costs. Construction quality varies significantly across price tiers:

- Budget Stock Cabinets: Particleboard boxes with veneer or laminate exteriors, basic joinery, limited warranty. Expected lifespan 10-15 years.

- Quality Semi-Custom: Plywood boxes with hardwood face frames, dovetail drawer construction, enhanced warranties. Expected lifespan 20-30 years.

- Premium Custom: Solid plywood construction throughout, mortise-and-tenon joinery, custom dimensioning. Expected lifespan 30-50+ years.

The construction quality difference matters enormously for longevity. Particleboard boxes deteriorate when exposed to moisture and stress, while plywood boxes resist moisture and maintain structural integrity through decades of use.

Doors, Drawer Fronts, and Finishes: While included in cabinet pricing, door upgrades significantly impact total costs. Thermofoil doors on stock cabinets add minimal cost, but upgrading to solid wood doors can increase cabinet prices by 30-50%. Specialty finishes like distressed, glazed, or painted add another 10-25% premium.

Hardware and Internal Organizational Features: Modern cabinet features add both cost and tremendous functional value:

- Soft-Close Mechanisms: $5-$15 per door/drawer – dramatically improves usability and extends cabinet life

- Pull-Out Organizers: $75-$200 each – maximizes storage efficiency

- Lazy Susans: $50-$150 each – essential for corner cabinet access

- Drawer Dividers and Inserts: $30-$100 each – keeps contents organized

These features quickly add up. A well-appointed kitchen with organizational inserts throughout can add $1,500-$3,500 to base cabinet costs. For DIY-minded homeowners, cabinet organization systems allow you to add these features after installation at reduced cost.

Delivery and Staging: Cabinet shipping costs $200-$800 depending on distance and order size. Custom cabinets shipped from distant manufacturers can exceed $1,000 for delivery alone. This often-overlooked expense deserves budget consideration.

Professional Installation Labor

Professional installation labor represents 20-35% of total replacement costs, typically $50-$150 per linear foot for complete installation. The process includes:

- Demolition and Removal: 4-8 hours for average kitchens to safely remove existing cabinets

- Wall Preparation and Repair: 2-6 hours patching holes, ensuring walls are level and plumb

- Cabinet Installation: 12-24 hours for precise leveling, alignment, and secure mounting

- Hardware and Adjustment: 4-8 hours installing drawer slides, hinges, handles, and final adjustments

Installation complexity significantly impacts labor costs. Simple layouts with standard cabinet sizes allow faster installation at lower costs. Custom configurations requiring extensive scribing, fitting, and alignment demand more time. Peninsula and island cabinets require additional support structure and coordination with electrical/plumbing trades, adding $500-$1,500 to labor costs.

Related Costs and Contingencies

Cabinet replacement rarely exists in isolation. Most projects require coordinated work adding substantial costs beyond cabinets themselves:

Countertop Work: If keeping existing countertops, removal and reinstallation costs $500-$1,500. However, most countertop materials can’t be reused once removed. Laminate may survive careful removal, but tile, granite, and quartz typically require replacement when disturbed, adding $2,000-$8,000+ to total project costs. Read our complete kitchen countertop comparison guide for detailed pricing and material analysis.

Flooring Repairs or Replacement: Removing cabinets exposes flooring that may not extend beneath the old cabinet footprint, creating visible lines where new cabinets sit. Patching costs $300-$1,500 depending on materials and whether matching products remain available. If flooring requires complete replacement, budget $2,000-$6,000 for average kitchens. See our kitchen flooring cost guide for detailed pricing by material type.

Electrical and Plumbing Adjustments: Layout changes often necessitate moving outlets, switches, undercabinet lighting, or plumbing lines. Electrical work runs $200-$800 for typical adjustments, while plumbing modifications cost $300-$1,200 depending on complexity.

Painting and Wall Repair: Cabinet removal damages walls requiring patching and repainting. Budget $500-$1,500 for professional paint work in average kitchens, or tackle this as a DIY project using quality supplies from Amazon’s painting section.

Disposal Costs: Removing old cabinets generates significant waste requiring proper disposal. Dumpster rental or hauling services add $300-$600 to project costs. Some contractors include disposal in their quotes while others charge separately.

Side-by-Side Cost Comparison by Budget Tier

Direct cost comparisons illuminate the true financial differences between refacing and replacement. This analysis for an average 200-square-foot kitchen with 25 linear feet of cabinetry reveals exactly how much you’ll save—or spend—with each approach.

Budget-Tier Comparison (Value-Focused Options)

Refacing (Laminate Veneer, Thermofoil Doors, Basic Hardware):

- Material costs: $2,200-$3,500

- Professional labor: $2,000-$3,000

- Total: $4,500-$6,500

- Timeline: 3-5 days with minimal kitchen disruption

- Expected lifespan: 10-15 years

Replacement (Stock Cabinets, Basic Features, Standard Sizes):

- Cabinet costs: $4,000-$6,500

- Installation labor: $1,800-$2,800

- Related costs (countertop reinstallation, minor wall repair, disposal): $1,000-$2,200

- Total: $6,800-$11,500

- Timeline: 7-12 days with complete kitchen shutdown during installation

- Expected lifespan: 12-18 years

Savings Analysis: Budget-tier refacing saves $2,300-$5,000 (34-43%) compared to stock cabinet replacement. This represents significant savings for homeowners primarily concerned with cosmetic updates while maintaining existing layouts. The cost differential could fund new appliances, improved lighting, or remain in emergency savings.

Mid-Tier Comparison (Quality Balance)

Refacing (Wood Veneer, Solid Wood Doors, Crown Molding, Soft-Close Hardware):

- Material costs: $4,800-$7,000

- Professional labor: $3,500-$5,500

- Total: $8,300-$12,500

- Timeline: 4-7 days with partial kitchen functionality maintained

- Expected lifespan: 15-20 years

Replacement (Semi-Custom Cabinets, Soft-Close Features, Organizational Inserts):

- Cabinet costs: $9,000-$15,500

- Installation labor: $2,800-$4,500

- Related costs (countertop work, electrical adjustments, flooring patch, painting, disposal): $3,500-$6,000

- Total: $15,300-$26,000

- Timeline: 10-16 days requiring temporary kitchen setup

- Expected lifespan: 20-28 years

Savings Analysis: Mid-tier refacing saves $7,000-$13,500 (46-52%) compared to semi-custom replacement. At this quality level, refacing delivers professional results closely approaching the visual quality of new cabinets while avoiding the disruption and ancillary costs of full replacement. This represents the sweet spot where refacing provides maximum value for most homeowners.

Premium-Tier Comparison (High-End Options)

Refacing (Premium Wood Veneer, Custom Solid Wood Doors, Decorative Glass Inserts, Designer Hardware):

- Material costs: $7,500-$11,000

- Professional labor: $5,500-$8,000

- Total: $13,000-$19,000

- Timeline: 6-9 days with careful sequencing to minimize disruption

- Expected lifespan: 18-22 years

Replacement (Custom Cabinets, Premium Features, Layout Modifications):

- Cabinet costs: $18,000-$38,000+

- Installation labor: $4,500-$9,000

- Related costs (new countertops, significant electrical/plumbing work, flooring replacement, extensive painting, disposal): $9,000-$16,000

- Total: $31,500-$63,000+

- Timeline: 16-30 days requiring complete kitchen relocation

- Expected lifespan: 30-50+ years

Savings Analysis: Premium refacing saves $18,500-$44,000 (59-70%) compared to custom replacement. However, at this budget level, homeowners often prioritize layout optimization and modern functionality over cost savings alone. The additional investment in custom replacement provides complete design freedom, potential layout improvements, and maximum longevity that may justify higher costs for long-term homeowners.

The True Cost of Kitchen Disruption

Financial comparisons don’t capture the full cost of kitchen unavailability. During full replacement, families typically face:

- Eating out more frequently: $500-$1,800 over 2-3 weeks

- Disposable plates, utensils, and basic supplies: $100-$200

- Limited food storage and preparation capability

- Significant stress managing daily routines without functional kitchen

- Potential vacation time from work to manage contractor access

Refacing minimizes these disruptions substantially. Most families maintain basic kitchen functionality throughout the project, experiencing only 1-2 days of complete shutdown versus 10-16 days for replacement. This difference alone can justify refacing for busy households unable to accommodate extended kitchen unavailability.

Durability and Lifespan: How Long Each Option Lasts

Cost comparisons mean little without understanding how long each investment lasts. The durability and expected lifespan of refaced versus replaced cabinets depend heavily on material quality, installation craftsmanship, and ongoing maintenance.

Cabinet Refacing Longevity (10-20+ Years)

Professional cabinet refacing typically lasts 15-20 years when executed with quality materials and proper installation, with some installations exceeding 25 years. The limiting factor is usually the structural integrity of existing cabinet boxes rather than the refacing materials themselves.

High-quality wood veneer applied to cabinet exteriors proves remarkably durable, often outlasting the homeowner’s tenure in the property. Modern contact adhesives create bonds stronger than the wood substrate when properly applied. Solid wood replacement doors easily last 20-30 years with normal use, matching or exceeding the lifespan of doors on new cabinets.

Material Impact on Longevity:

- Laminate/Thermofoil: 10-15 years – Budget option that may show edge peeling or surface wear over time, particularly in high-moisture areas near sinks and dishwashers

- Wood Veneer: 15-20 years – Superior durability with proper care, resists moisture better than laminate, develops attractive patina over time

- Solid Wood Doors: 20-30+ years – Maximum durability, can be refinished if desired, authentic wood grain improves with age

The critical variable remains existing cabinet box condition. Well-constructed plywood boxes from the 1980s-1990s often outlast cheaper particleboard cabinets installed in the 2000s-2010s. If your cabinet boxes feature solid plywood construction with proper joinery, refacing can genuinely deliver decades of additional service.

However, refacing doesn’t address fundamental structural issues. If cabinet boxes suffer from water damage, joint separation, or construction defects, refacing merely applies cosmetic improvements to failing infrastructure. Research from the National Kitchen & Bath Association indicates that cabinet box condition is the primary predictor of refacing longevity.

Cabinet Replacement Longevity (12-50+ Years)

New cabinet longevity varies dramatically by construction quality, ranging from budget options lasting barely over a decade to premium custom cabinets exceeding 50 years:

Stock Cabinets (12-18 Years): Built with particleboard boxes and basic construction, stock cabinets from home improvement retailers typically show significant wear within 12-15 years. Particleboard deteriorates when exposed to moisture, hinges loosen in particleboard face frames, and finish quality degrades faster than higher-quality options.

Semi-Custom Cabinets (20-28 Years): Constructed with plywood boxes, hardwood face frames, and quality hardware, semi-custom cabinets from manufacturers like KraftMaid or Thomasville commonly deliver 20-28 years of service. These represent the sweet spot for most homeowners balancing quality against cost.

Premium Custom Cabinets (30-50+ Years): Built from solid plywood with dovetail joinery, mortise-and-tenon face frames, and premium finishes, custom cabinets routinely exceed 30-50 years. Many homes still feature original custom cabinets from the 1970s-1980s in excellent condition, testament to quality construction longevity.

Construction Details That Matter:

- Box Material: Plywood resists moisture and maintains structural integrity far better than particleboard. This single factor most influences cabinet lifespan.

- Joinery Quality: Dovetail drawer construction, doweled cabinet corners, and mortise-and-tenon face frames last decades longer than stapled or simple butt joints.

- Hardware Quality: Soft-close hinges and ball-bearing drawer slides reduce impact stress, extending cabinet life by years compared to basic hardware.

- Finish Durability: Catalyzed conversion varnish finishes used on quality cabinets resist wear, moisture, and chemicals far better than basic lacquer finishes on budget options.

Cost-Per-Year Value Analysis

Analyzing cost-per-year of service provides perspective beyond initial investment, revealing the true long-term value of each option:

- Budget Refacing ($5,000 / 12 years): $417 per year

- Quality Refacing ($10,000 / 18 years): $556 per year

- Stock Replacement ($9,000 / 15 years): $600 per year

- Semi-Custom Replacement ($20,000 / 25 years): $800 per year

- Custom Replacement ($40,000 / 40 years): $1,000 per year

This analysis reveals that quality refacing of solid existing cabinets often provides the best long-term value on an annual cost basis. However, replacing failing cabinets with quality new construction delivers better value than refacing poor-quality boxes requiring replacement in 5-7 years anyway.

The key insight: refacing works best when existing cabinet boxes have substantial remaining life. Replacement makes more sense when boxes approach end-of-life regardless of cosmetic condition.

When Cabinet Refacing Makes Financial Sense

Cabinet refacing excels in specific situations where cabinet boxes remain structurally sound but visual appearance has degraded significantly. Understanding these ideal scenarios helps you determine if refacing suits your specific situation and budget constraints.

Ideal Candidates for Cabinet Refacing

Solid Cabinet Box Construction: If your existing cabinets feature plywood boxes with solid wood face frames and quality joinery, they’re excellent refacing candidates possessing decades of remaining structural life despite outdated aesthetics. Cabinets from the 1980s-1990s often used superior construction compared to modern budget options, making them perfect for refacing rather than replacing.

To assess your cabinet box quality, examine inside base cabinets. Solid plywood shows uniform layers throughout the material thickness. Particleboard reveals a compressed sawdust core. Check corner joints for solid doweled or dado construction versus simple butt joints with staples. Test face frames for solid attachment without looseness or separation.

Satisfactory Current Layout: Homeowners happy with their kitchen’s functional layout but tired of outdated appearance find refacing ideal. If your storage quantity, counter space distribution, and work triangle function well for your cooking and family needs, changing appearance without disrupting layout makes perfect sense.

Consider whether you consistently struggle with storage inadequacy, awkward workflow, or functional limitations. If your answer is no, refacing addresses cosmetic concerns without unnecessary overhaul. Similar principles apply to bathroom remodeling decisions where layout satisfaction determines whether refinishing or replacement makes more sense.

Budget Constraints (Under $12,000 Available): When kitchen updates must stay within limited budgets, refacing delivers dramatic visual transformation for 40-60% less than replacement. The $6,000-$14,000 cost savings enable upgrades in other areas—better countertops, improved lighting, new flooring, or quality appliances—creating more comprehensive kitchen improvements within overall budget.

Quick Timeline Requirements: Projects requiring rapid completion benefit from refacing’s shorter timeline. Whether preparing a home for sale, working around life events like weddings or extended family visits, or minimizing disruption to busy household routines, 3-7 day refacing projects versus 14-28 day replacements offer significant lifestyle advantages.

Cosmetic Concerns Primarily: When your primary complaints involve appearance—dated colors, worn finishes, outdated hardware, style mismatches—rather than functionality, refacing directly addresses these concerns without unnecessary replacement. This situation particularly suits homeowners who purchased homes with outdated but structurally sound kitchens.

Practical Situations Favoring Refacing

Recent Home Purchases: Buyers who love location and layout but dislike kitchen aesthetics represent perfect refacing scenarios. Investing $8,000-$12,000 in refacing leaves budget for other home improvements rather than consuming $20,000-$30,000 on complete cabinet replacement early in homeownership.

Pre-Sale Preparations: Homeowners preparing to sell benefit from refacing’s strong return on investment. According to Remodeling Magazine’s Cost vs. Value Report, minor kitchen remodels including refacing return 72-96% of cost in increased sale price, while major replacements typically return only 50-70%. Updated cabinet appearance significantly improves kitchen appeal without major investment.

Rental Properties: Investment property owners benefit from refacing’s lower cost and shorter disruption period. The reduced investment and minimal vacancy time while maintaining tenant appeal creates ideal economics for rental unit updates. Properties can be refaced between tenants over long weekends, minimizing lost rental income.

Environmental Consciousness: Homeowners prioritizing sustainability appreciate refacing’s environmental benefits. Keeping existing cabinet boxes out of landfills while updating aesthetics aligns with reduce-reuse principles, avoiding the environmental impact of manufacturing and transporting entirely new cabinets.

Financial Breakpoints for Refacing

The refacing decision makes strong financial sense when replacement costs exceed refacing by $8,000 or more. At this differential, the additional investment in replacement requires clear justification through layout improvements, structural necessities, or dramatically increased functionality.

When comparing mid-tier refacing ($8,000-$12,000) against semi-custom replacement ($20,000-$28,000), the $12,000-$16,000 difference funds significant improvements elsewhere:

- Complete bathroom remodel: $8,000-$15,000 (see our bathroom remodeling guide)

- New kitchen flooring: $2,000-$6,000 (explore options in our flooring comparison guide)

- Quality appliance package: $3,000-$8,000

- Window replacement throughout home: $5,000-$12,000

- Emergency fund or retirement savings

This opportunity cost deserves serious consideration in decision-making, particularly for homeowners with multiple improvement priorities competing for limited budgets.

When Cabinet Replacement Is Necessary

Despite refacing’s cost advantages, certain situations demand complete cabinet replacement. Recognizing these scenarios prevents wasting money on refacing when replacement is inevitable within years.

Structural Failures Requiring Replacement

Water Damage: Cabinets with swollen particleboard, delaminating surfaces, musty odors, or visible mold growth require complete replacement. Water damage compromises structural integrity beyond cosmetic repair capability. Even if refacing temporarily improves appearance, underlying deterioration continues progressing, leading to complete failure within 2-5 years.

Check sink base cabinets and areas around dishwashers particularly carefully. Run your hand along bottom panels feeling for soft spots or swelling. Open doors and smell for musty odors indicating hidden moisture damage. Any evidence of water infiltration or resulting damage mandates replacement rather than refacing.

Joint Separation and Structural Instability: Cabinet boxes pulling apart at corners, bottoms sagging from weight, face frames separating from boxes, or doors no longer closing properly indicate structural failure beyond refacing’s repair capability. Attempting to reface failing boxes wastes money on cosmetic improvements while ignoring critical structural issues.

Test cabinet stability by grasping corners and attempting to rack (twist) the cabinet. Solid boxes resist movement. Failing boxes show flex, creaking, or visible joint movement. Check face frame attachment by pulling gently—secure frames don’t budge while failing attachments show movement or gaps.

Pest Damage and Wood Rot: Termite or carpenter ant damage, wood rot from long-term moisture exposure, or other infestations require complete removal and replacement. These problems extend beyond cabinet surfaces into wall structures, demanding comprehensive remediation impossible with surface-only refacing.

Functional Limitations Demanding Replacement

Inadequate Storage Capacity: Kitchens lacking sufficient storage despite organized use need layout reconfiguration that refacing cannot provide. Adding upper cabinets where none exist, increasing base cabinet depth from 21″ to 24″, or incorporating pantry cabinets requires new construction rather than surface updates.

Poor Layout Design and Workflow Issues: Kitchens with inefficient work triangles, inadequate counter space, or awkward traffic flow benefit more from layout optimization than cosmetic updates. Replacement enables comprehensive redesign addressing functional deficiencies refacing cannot touch:

- Moving the sink location for better workflow

- Adding islands or peninsulas for additional counter space and seating

- Reconfiguring appliance locations for improved efficiency

- Creating dedicated prep zones or coffee stations

Appliance Size Mismatches: Modern appliances not fitting existing cabinet openings, insufficient clearance for new refrigerators or ranges, or desire for professional-sized equipment often necessitates cabinet reconfiguration possible only through replacement. Standard cabinet heights of 30″ don’t accommodate modern 36″ refrigerators. Professional ranges require different clearances than builder-grade models.

Accessibility and Universal Design Needs: Aging homeowners requiring wheelchair accessibility, reduced reach distances, or ergonomic improvements need cabinet height adjustments, roll-out shelving, and specialized features impossible to retrofit into existing cabinet boxes. Lowering wall cabinets, removing base cabinets for knee space, or installing pull-down shelf mechanisms all require replacement.

Quality Considerations

Low-quality existing cabinets built with particleboard boxes, stapled joints, and thin veneers don’t justify refacing investment. Even with new doors and veneer, underlying inferior construction limits longevity to 8-12 years. Spending $8,000-$12,000 refacing cabinets requiring replacement in 5-7 years anyway makes poor financial sense compared to investing in quality new cabinets lasting 20-30 years.

Cabinet dimensions also matter for functional value. Standard 12-inch deep upper cabinets from the 1970s-1980s offer significantly less storage than modern 13-inch or 15-inch depths. Replacing older shallow cabinets with deeper modern construction provides substantial functional improvement justifying additional investment beyond simple refacing.

Long-Term Home Plans

Homeowners planning 15+ years in their current residence often prioritize long-term value over immediate cost savings. If you love your home and anticipate decades of continued use, investing in quality custom cabinets precisely matching your needs delivers better lifetime value than refacing acceptable-but-not-ideal existing cabinets.

Calculate the decision using expected years of use. If planning 20+ years of occupancy, spending an additional $12,000-$18,000 for replacement versus refacing translates to only $600-$900 annually for significantly improved functionality and extended lifespan. The investment makes increasing sense with longer ownership timelines.

Major renovations involving structural changes, room additions, or complete kitchen repositioning require cabinet replacement regardless of existing cabinet condition. The comprehensive nature of such projects makes retaining old cabinets impractical even when structurally sound.

Hidden Costs Most Homeowners Miss (Add 15-25% to Budget)

Both refacing and replacement involve expenses beyond obvious material and labor costs. Awareness of these hidden costs prevents budget-busting surprises mid-project. Industry research shows actual project costs typically exceed initial quotes by 15-25% due to these commonly overlooked expenses.

Hidden Refacing Costs

Cabinet Structural Repairs: Many refacing bids assume structurally sound cabinets. Discovering loose joints during preparation, damaged hinges requiring wood filler repair, failing drawer boxes needing replacement, or warped shelves adds $200-$1,200 to project costs. Reputable contractors inspect thoroughly before quoting, but budget 10-15% contingency for unexpected repairs regardless.

Veneer Matching and Color Coordination: Matching new veneer to existing finished ends or areas that won’t be refaced sometimes requires custom color matching, adding $200-$600 to material costs. Perfect matches prove difficult with natural wood variations, particularly when original finishes have aged or faded over years.

Hardware Complications and Modifications: Switching from exposed hinges to European hidden hinges requires drilling new holes in precise locations. If existing doors are solid wood and being reused for some areas, this modification costs $15-$30 per door for labor and potential wood filler repairs. New drawer slides fitting old drawer boxes sometimes require mounting plate adapters, adding $100-$400 total depending on drawer quantity.

Incomplete Coverage Issues: Budget refacing quotes sometimes exclude interior painting ($300-$900), end panel replacement ($200-$700), toe kick updates ($150-$450), or crown molding installation ($400-$1,200). These elements remaining obviously old next to new doors and veneer diminish overall results. Clarify exactly what’s included in quotes before signing contracts.

Appliance Trim and Finishing Details: Refaced cabinets may not align perfectly with existing appliance trim kits, requiring new panels or modifications costing $150-$500. Gaps between new doors and appliances sometimes need decorative filler strips adding $75-$200.

Hidden Replacement Costs

Cabinet Modifications for Appliances: New cabinets using standard sizing sometimes don’t perfectly accommodate existing appliances. Custom refrigerator panels ($300-$800), range trim kits ($150-$400), dishwasher filler strips ($100-$250), or microwave cabinet modifications ($200-$500) add costs not included in cabinet quotes.

Crown Molding and Decorative Trim: Many cabinet quotes exclude crown molding, treating it as optional upgrade. However, the gap between cabinet tops and ceiling looks unfinished without it in most homes. Crown molding installation costs $8-$25 per linear foot depending on complexity, adding $400-$1,500 to average kitchens. For DIY-inclined homeowners, crown molding materials reduce costs, though professional installation is recommended for best results.

Countertop Templating Delays and Complications: New cabinets require countertop templating after installation, delaying countertop fabrication 1-3 weeks beyond cabinet completion. This extended timeline may require temporary food preparation solutions, extend project duration beyond anticipated schedules, and potentially trigger change orders if cabinet installation reveals countertop compatibility issues.

Permit and Inspection Fees: Significant kitchen remodels often require building permits costing $200-$800 depending on jurisdiction and project scope. Inspections for electrical or plumbing work add delays and potential correction costs if work doesn’t meet code. Some localities require licensed contractors for permitted work, preventing lower-cost handyman options.

Temporary Kitchen Setup and Living Expenses: Extended replacement timelines necessitate temporary solutions adding real costs:

- Microwave, toaster oven, and small appliances for temporary prep area: $150-$400 if not owned

- Disposable plates, utensils, and food storage: $100-$250

- Increased restaurant meals and takeout: $500-$2,000 for 2-4 weeks

- Potential hotel stays during intensive work periods: $500-$1,500

Finish Coordination and Paint Touch-Ups: New cabinets often expose wall areas requiring repainting beyond simple touch-ups. Walls may have faded, creating color mismatches between exposed and previously covered areas. Full room repainting adds $500-$1,200 to project costs.

2026 Remodeling Cost Guide

Don’t get ripped off. See real pricing for bathrooms, kitchens, and HVAC.

Updated for 2026 Market Rates

Universal Hidden Costs (Both Options)

Design and Planning Time Investment: Homeowners often undervalue their own time invested in planning ($800-$2,000 opportunity cost based on 15-60 hours), selecting materials, meeting contractors, and managing projects. This time has real value whether measured in vacation days from work, weekend hours with family, or alternative productive activities.

Change Orders During Installation: Discovering problems after work begins commonly generates change orders adding 10-20% to quoted prices. Unexpected issues include unforeseen water damage, electrical work needed for code compliance, structural repairs in walls or floors, and design modifications when seeing installed work.

Post-Completion Touch-Ups and Adjustments: Final adjustments (door realignment, hardware tightening, minor repairs, finish touch-ups) often occur weeks after initial installation. While usually covered under warranty, they require schedule coordination and sometimes vacation time from work for access. Budget at least one follow-up visit into timeline expectations.

Learning Curve on New Cabinets: This isn’t a dollar cost but represents real adjustment time learning new cabinet layouts, organizational systems, soft-close mechanisms requiring different use patterns, and optimized storage organization to utilize new features effectively.

DIY vs. Professional Installation: True Cost Analysis

Many homeowners consider DIY installation to reduce costs significantly. While possible for skilled individuals, both refacing and replacement demand abilities, tools, and time investments that often justify professional installation when comprehensive analysis includes all factors.

DIY Cabinet Refacing

Material Costs for DIY: DIY refacing kits from companies like Rust-Oleum Cabinet Transformations offer budget-friendly coating systems starting at $200-$400 for basic finish coverage of 100 square feet. More comprehensive DIY solutions including replacement doors and veneer sheets cost $2,500-$5,000 for average kitchens when purchasing materials directly.

Quality DIY refacing materials are available through Amazon’s cabinet refacing section, offering veneer sheets, contact cement, edge banding, and necessary supplies at competitive prices.

Tool Requirements and Investment: Successful DIY refacing requires specific tools many homeowners don’t own:

- Veneer roller for bubble-free application: $15-$35

- Contact cement and applicator tools: $40-$90

- Edge trimming knife and replacement blades: $25-$60

- Hinge drilling jig for European hinges: $80-$180

- Quality cordless drill/driver: $100-$250 if not owned

- Measuring and marking tools: $30-$70

- Safety equipment (respirator, eye protection): $30-$60

Total tool investment reaches $300-$700 for homeowners lacking these specialized items. These tools have limited reuse value beyond the immediate project for most homeowners. Consider cabinet installation tool sets that bundle commonly needed items at package pricing.

Time Investment Reality: Expect 50-90 hours for complete DIY refacing in average kitchens, working evenings and weekends across 3-4 weeks. This assumes no major complications or learning curve errors requiring material replacement. Realistic timeline includes:

- Planning, measuring, ordering: 8-12 hours

- Surface preparation and repair: 10-16 hours

- Veneer application: 15-25 hours (including learning curve)

- Door and hardware installation: 12-20 hours

- Final adjustments and corrections: 5-12 hours

Quality and Results Expectations: The quality gap between DIY and professional work shows clearly in final results. Professionals achieve tight veneer application without bubbles or edge lifting, perfectly aligned doors with consistent gaps throughout, smooth hardware operation from precise installation, and professional-grade finish quality.

DIY efforts typically reveal minor imperfections invisible to casual observers but noticeable to occupants: slight bubbles under veneer in corners, doors with minor misalignment requiring periodic adjustment, hardware installation requiring occasional tightening, and visible seams or joints in veneer application.

Financial Analysis: DIY refacing potentially saves $3,500-$6,000 in professional labor costs. However, comprehensive analysis requires considering:

- Tool investment: $300-$700 (minimal resale value)

- Material waste from errors: $200-$500 typically

- Time investment value: 60-80 hours × your hourly wage or opportunity cost

- Quality differential and potential future corrections

If your time is worth $30/hour in alternative uses (family time, paid work, other projects), 70 hours represents $2,100 opportunity cost. Combined with tools ($500) and material waste ($300), actual DIY savings reduce from $5,000 to approximately $2,100—still significant but representing $30/hour value for time invested rather than $70-85/hour apparent savings.

DIY Cabinet Replacement

Material Costs for DIY: Installing stock cabinets from home improvement stores represents achievable DIY work for skilled homeowners with construction experience. Cabinet costs of $4,500-$9,000 versus full installed prices of $10,000-$18,000 create potential savings of $5,500-$9,000 in labor.

Tool and Supply Requirements: Cabinet installation demands considerable tools and supplies:

- Laser level for accurate cabinet leveling: $80-$250

- Stud finder for secure wall mounting: $20-$70

- Quality cordless drill/driver and impact driver: $150-$400

- Cabinet installation screws and anchors: $40-$100

- Shims for leveling (extensive quantity needed): $30-$70

- Scribing tools for fitting against walls: $25-$60

- Drywall saw for outlet modifications: $15-$40

- Safety equipment and protective gear: $40-$80

Total tool investment reaches $400-$1,100 for homeowners lacking these items. Quality tools from Amazon’s professional tool section provide reliable performance at various price points.

Time Investment Reality: Cabinet installation extends considerably for DIYers versus professionals. Realistic timeline expectations:

- Removing existing cabinets safely: 8-16 hours

- Wall preparation and repair: 6-12 hours

- Installing upper cabinets: 16-30 hours (including leveling, scribing, mounting)

- Installing base cabinets: 12-24 hours

- Hardware installation and door alignment: 8-16 hours

- Final adjustments and corrections: 6-12 hours

Total: 56-110 hours spread across 5-8 weekends for most DIYers. Complex kitchens with islands, peninsulas, or extensive runs can double these estimates.

Skill Requirements and Challenges: Successful cabinet installation demands considerable expertise:

- Finding and marking wall studs for secure mounting

- Installing secure ledger boards for upper cabinets (holding 60-100 lbs each)

- Shimming for perfect level across uneven floors and out-of-plumb walls

- Precise scribing for proper fit against irregular walls

- Secure fastening without splitting cabinet materials or stripping screws

- Coordinating with electrical and plumbing for proper clearances

Mistake Costs and Risk Factors: Errors prove costly in DIY installations:

- Incorrect measurements requiring cabinet reordering: $500-$2,000+

- Damage from improper handling or installation: $200-$1,500

- Out-of-level installation requiring removal and reinstallation: 15-30 hours additional time

- No insurance coverage for damage (professional installers carry liability insurance)

Physical Demands: Cabinet installation is physically demanding work. Upper cabinets weigh 60-100 pounds and must be held in position while securing to walls—requires two-person teams minimum. Base cabinets require extensive kneeling, bending, and reaching into confined spaces. Back strain, knee stress, and general fatigue are common complaints from DIY installers.

Financial Analysis: Comprehensive DIY cabinet replacement cost analysis:

- Potential labor savings: $5,500-$9,000

- Minus tool investment: $400-$1,100

- Minus likely errors/waste: $300-$800

- Minus opportunity cost (80 hours × $30/hour): $2,400

- Net savings: $2,400-$5,300

Actual savings of $2,400-$5,300 represent $30-$66/hour value for time invested—meaningful savings but requiring honest assessment of your skills, available time, and tolerance for potential complications.

When DIY Makes Sense

DIY installation makes most sense when you possess relevant construction experience, have available tools already, enjoy hands-on projects as hobby/recreation (time investment is pleasure rather than burden), can tolerate imperfect results without stress, and have flexible schedules accommodating extended timelines.

DIY rarely makes sense when you lack relevant skills or tools, have limited available time, need professional-quality results for home sale, can’t accommodate extended kitchen unavailability, or value your time at rates exceeding $40-50/hour in alternative uses.

Professional Value Proposition

Professional installation delivers speed (completion in days versus weeks), quality (proper techniques and specialized tools ensuring lasting results), warranty coverage (repairs for installation errors and defects), expertise (problem-solving for unexpected complications), and insurance protection (liability coverage for damage during work).

For refacing, professional installation adds $2,800-$6,000 to material costs but delivers superior veneer application, perfect door alignment, and completion in 3-7 days versus 3-4 weeks DIY. For replacement, professional installation adds $2,500-$6,000 but ensures proper leveling, secure attachment, code compliance, and warranty protection against future issues.

Many homeowners find professional installation worthwhile despite higher costs, particularly for projects impacting daily living like kitchen renovations where extended DIY timelines create significant lifestyle disruption.

Return on Investment: Resale Value and Long-Term Ownership

Kitchen improvements deliver varying returns on investment depending on project scope, quality level, and local real estate markets. Understanding ROI implications helps justify renovation decisions within broader financial planning whether you’re selling soon or staying long-term.

Refacing ROI for Home Sales (72-96% Return)

According to Remodeling Magazine’s Cost vs. Value Report, minor kitchen remodels including cabinet refacing return approximately 72-83% of investment at resale nationally. However, recent data shows even higher returns of up to 96% for minor kitchen updates in certain markets, particularly for homes in mid-price ranges where updated appearance matters most to buyers.

A $9,000 refacing project might increase home value by $7,500-$9,000, achieving 83-100% ROI. The same kitchen with $24,000 cabinet replacement might increase value by $16,000-$19,000, achieving only 67-79% ROI. The lower refacing cost relative to value addition creates better percentage returns even when total value increase may be similar.

Market Conditions Impact Returns: Hot markets with low inventory see updated kitchens command premiums as differentiators among competing listings. In slower markets or areas with high inventory, kitchen updates prevent value discounts more than creating premiums—you recover costs rather than profit from improvements.

Competitive analysis of similar properties reveals whether kitchen updates deliver competitive advantage or simply maintain market parity. In neighborhoods where most homes have updated kitchens, dated cabinets decrease sale price more than updated cabinets increase it. Refacing brings you to parity at lower cost than replacement.

Timing Considerations for Maximum ROI: Homeowners planning sales within 1-3 years benefit most from strategic refacing updates. The immediate visual impact and moderate cost investment position homes competitively without over-improving for neighborhood comps.

Those planning 5+ years of continued residence should prioritize personal preferences and functionality over pure ROI calculations, as long-term market conditions remain unpredictable. Home improvements should serve your needs first, with resale considerations secondary for long-term ownership.

Replacement ROI for Home Sales (50-75% Return)

Complete cabinet replacement shows mixed ROI depending on project scope and quality level. Budget stock cabinet installations ($12,000-$18,000) often return 60-75% of cost in increased sale price. Premium custom installations ($35,000-$60,000+) typically return only 50-65%, as ultra-high-end improvements exceed buyer expectations in most markets.

The ROI Sweet Spot: Quality semi-custom installations ($18,000-$28,000) combining modern functionality, durable construction, and appealing aesthetics without over-improving for neighborhood comparables commonly return 70-85% of cost. These projects deliver maximum value for investment in most markets.

Layout Improvements and Functional Upgrades: Replacement projects addressing clear functional deficiencies deliver better returns than purely aesthetic replacements. Adding islands where space permits, improving storage in previously cramped kitchens, modernizing appliance integration, or optimizing work triangles creates functional value buyers recognize and reward in purchase offers.

Regional Variations in ROI: Kitchen remodel returns vary by region:

- Western US: 75-85% returns on mid-range remodels

- Midwest: 70-80% returns

- Northeast: 65-75% returns

- South: 70-80% returns

Local market analysis with real estate professionals provides more accurate expectations for your specific area and price range.

Long-Term Ownership Value (Personal Use ROI)

Homeowners planning extended tenure should evaluate personal utility value alongside resale ROI. The satisfaction of using a beautiful, functional kitchen daily for 15-20 years justifies investments beyond pure financial returns measured in resale value.

Annual Cost Analysis for Long-Term Value: Calculate personal value through annual cost over expected ownership period:

- Refacing ($10,000 / 18 years remaining ownership): $556 per year for dramatically improved aesthetics while maintaining adequate function

- Replacement ($25,000 / 20 years remaining ownership): $1,250 per year for optimized function, improved storage, and personal design preferences

If refacing delivers daily satisfaction through improved aesthetics while functional adequacy remains acceptable, $556 annually provides excellent personal value regardless of resale ROI. Your kitchen serves you 2-3 times daily for two decades—that’s 10,000-15,000 uses justifying moderate annual costs for enjoyment.

Conversely, replacement transforming cramped, poorly organized kitchens into spacious, efficient workspaces delivers compounding value through thousands of cooking experiences, family gatherings, and daily routines. The functional improvements justify higher annual costs through dramatically enhanced utility and daily enjoyment.

Quality of Life Improvements: Consider non-financial value factors:

- Daily stress reduction from efficient, organized workspace

- Family gathering enhancement with improved functionality

- Cooking enjoyment increase from better workflow

- Pride in beautiful, updated living space

- Reduced time spent working around limitations

These quality-of-life improvements have real value impossible to quantify financially but contributing significantly to home satisfaction and daily wellbeing.

Tax and Appraisal Implications

Property Tax Assessment: Major kitchen renovations sometimes increase property tax assessments as municipalities reassess home values. While specific policies vary by jurisdiction, improvements adding substantial value ($15,000+) may trigger reassessment increasing annual property taxes $150-$600+. Factor this ongoing cost into ROI calculations for major replacement projects.

Refacing’s lower cost and minimal structural change less frequently triggers reassessment, though this varies by local tax policies and assessment practices.

Investment Property Tax Treatment: For rental properties, kitchen renovations may qualify for depreciation deductions spreading costs across 27.5 years (residential rental). Consult tax professionals regarding specific treatment, as both refacing and replacement can offer tax advantages for investment property owners, potentially improving effective ROI by 15-25% through tax benefits.

Making Your Decision: A Step-by-Step Framework

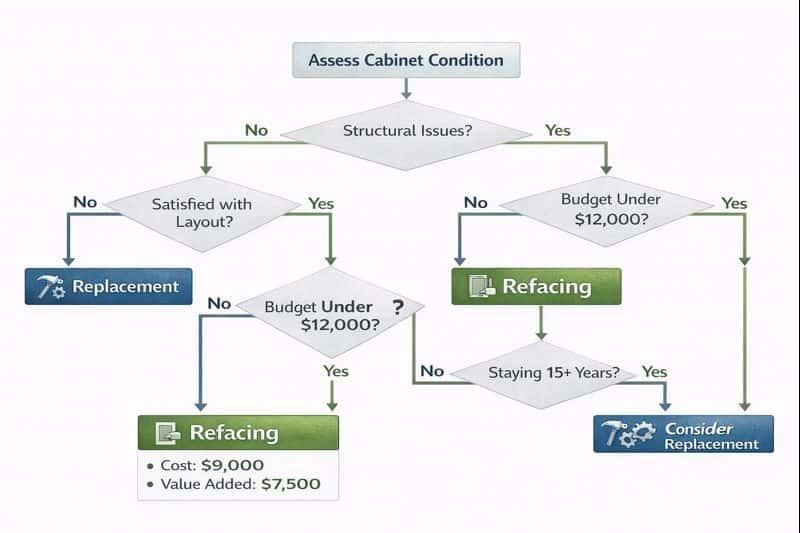

Armed with comprehensive cost knowledge, durability understanding, and ROI awareness, you can systematically evaluate whether refacing or replacement best suits your specific situation. This decision framework guides you through the analysis methodically.

Step 1: Assess Cabinet Box Structural Condition

Begin by thoroughly inspecting cabinet boxes for structural integrity:

Physical Inspection Checklist:

- Open doors and examine corner joints—should be tight without separation

- Check bottom panels for sagging or water damage—should be flat and solid

- Feel face frames for solid attachment to boxes—shouldn’t show movement

- Look inside sink base cabinets for water damage, mold, or swelling

- Examine drawer boxes for solid construction and proper operation

- Test cabinet box material—plywood shows uniform layers, particleboard reveals compressed sawdust core

- Rack (gently twist) cabinet boxes to test rigidity—solid boxes resist movement

Decision Criteria: If boxes show solid plywood construction with tight joints, no water damage, and minimal wear, they’re excellent refacing candidates providing decades of remaining service. If you find particleboard boxes with joint separation, water damage, structural issues, or construction defects, replacement becomes necessary regardless of cosmetic improvements refacing provides.

Step 2: Evaluate Functional Satisfaction

List specific functional issues beyond aesthetics honestly:

Functional Assessment Questions:

- Do you have adequate storage for your needs, or constantly struggle with space?

- Does the current layout provide efficient workflow between sink, stove, and refrigerator?

- Are counter spaces sufficient for food prep, appliance use, and serving?

- Do cabinet depths accommodate modern dishware, cookware, and appliances comfortably?

- Can you reach items easily, or do accessibility concerns exist?

- Would you benefit from modern features like pull-out organizers, soft-close mechanisms, or improved lighting?

Decision Criteria: If functional satisfaction is high with only aesthetic concerns, refacing addresses your primary needs efficiently and economically. If you’ve worked around functional limitations for years—inadequate storage, awkward workflow, insufficient counter space—replacement enabling layout optimization delivers value beyond cosmetic updates alone.

Step 3: Define Realistic Budget Parameters

Establish honest budget including appropriate contingency for unexpected costs:

Budget Development:

- Determine maximum comfortable spending without financial stress

- Add 15-20% contingency for unexpected costs and change orders

- Consider other home improvement priorities competing for funds

- Evaluate financing options if needed, calculating total cost including interest

- Compare opportunity costs—what else could these funds accomplish?

Decision Criteria: If budget allows only $6,000-$12,000, quality refacing delivers dramatic improvement within constraints and leaves funds for complementary upgrades like new lighting or improved flooring. If budget extends to $18,000-$30,000, evaluate whether functional improvements and extended lifespan justify additional replacement costs beyond refacing savings.

Step 4: Consider Timeline and Disruption Tolerance

Assess honestly your tolerance for kitchen unavailability and project disruption:

Lifestyle Impact Questions:

- Do you cook frequently at home, or rely more on dining out and convenience foods?

- Do you have alternative food preparation options (outdoor grill, garage setup)?

- Can you manage 10-20 days without full kitchen access?

- Do work schedules, family events, or other commitments limit available project windows?

- Are young children or elderly family members present requiring consistent routines?

Decision Criteria: Refacing’s 3-7 day timeline with minimal disruption suits busy households better than replacement’s 10-21 days of complete kitchen shutdown. However, homeowners with schedule flexibility, temporary living alternatives, or high tolerance for disruption can accommodate replacement timelines if functional improvements justify extended inconvenience.

Step 5: Evaluate Long-Term Home Plans

Consider expected tenure in the home realistically:

Ownership Timeline Assessment:

- Are you planning to sell within 1-3 years?

- Will you likely stay 5-10 years?

- Do you anticipate 15+ years of occupancy?

- Are there unknown factors (job changes, family growth) affecting timeline?

Decision Criteria: Planning to sell within 1-3 years favors refacing’s lower cost and strong ROI (72-96% return). Staying 5-10 years makes either option viable depending on functional needs and budget comfort. Planning 15+ years of occupancy encourages prioritizing personal preferences and functionality over cost minimization, as daily use value compounds over decades justifying higher replacement investment for optimized results.

Step 6: Obtain Multiple Professional Quotes

Get at least three detailed quotes for your preferred option ensuring apple-to-apple comparisons:

Quote Comparison Checklist:

- Verify identical materials specified (veneer type, door construction, hardware quality)

- Confirm complete labor scope included (prep work, installation, adjustments, cleanup)

- Compare warranty terms carefully (materials, workmanship, duration)

- Review timeline commitments and completion guarantees

- Ask about contractor experience, licensing, and insurance coverage

- Request references and examples of completed work

- Clarify payment schedules and deposit requirements

Budget refacing quotes using laminate veneer and thermofoil doors shouldn’t be compared against premium quotes with wood veneer and solid wood doors without acknowledging quality differences. Similarly, stock cabinet replacement quotes differ fundamentally from semi-custom or custom cabinet quotes in materials, construction, and expected lifespan.

Final Decision Matrix

Synthesize your analysis into clear decision criteria:

Choose Refacing If:

- Cabinet boxes are structurally sound (plywood construction, tight joints, no water damage)

- Current layout meets your functional needs adequately

- Budget is limited ($4,000-$12,000 range)

- Quick timeline is important (under 1 week preferred)

- ROI maximization is priority (planning to sell within 3 years)

- Environmental sustainability matters (keeping existing materials)

Choose Replacement If:

- Cabinet boxes show structural issues (water damage, joint separation, poor construction quality)

- Functional improvements are needed (layout changes, storage increases, accessibility modifications)

- Budget allows comprehensive updates ($15,000-$40,000+ range)

- Extended project timeline is acceptable (2-4 weeks manageable)

- Long-term home plans (10+ years) justify investment in ideal configuration

- Complete design control and custom features are priorities

Trust your analysis while remaining open to contractor insights during consultations. Experienced professionals often identify issues or opportunities you might miss, providing valuable perspective that can refine your decision before committing to either approach.

Remember that neither choice is permanent—cabinets can always be updated again in future years if needs or circumstances change. Make the best decision for your current situation rather than trying to anticipate every possible future scenario.

Frequently Asked Questions

How much cheaper is cabinet refacing compared to full replacement in 2026?

Cabinet refacing typically costs 30-55% less than full replacement for comparable quality levels in 2026. For an average kitchen with 25 linear feet of cabinetry, professional refacing ranges from $4,500-$12,000, while complete replacement costs $10,000-$35,000+. The exact savings depend on kitchen size, material selections, and project complexity.

Budget-tier refacing might save $2,300-$5,000 (34-43%) compared to stock cabinet replacement. Mid-tier refacing saves $7,000-$13,500 (46-52%) compared to semi-custom replacement. Premium refacing saves $18,500-$44,000 (59-70%) compared to custom cabinet replacement. These savings exclude additional replacement costs like countertop work ($500-$8,000), flooring repairs ($300-$6,000), and electrical adjustments ($200-$800) that refacing avoids entirely, potentially increasing total savings to 40-65% overall.

Can I reface cabinets that are 25-40 years old, and will they last?

Yes, if the cabinet boxes remain structurally sound with no water damage or joint separation. Cabinets built in the 1980s-1990s often used superior plywood construction that outlasts many modern budget cabinets, making them excellent refacing candidates capable of lasting another 15-20 years after professional refacing.

The key assessment factors are: cabinet box material (plywood is ideal, particleboard is problematic for longevity), joint integrity (corners should be tight without visible separation or movement), absence of water damage (no swelling, mold, musty odors, or delamination), and solid face frame condition (secure attachment without loosening). Older cabinets with plywood boxes and solid construction often outlast newer particleboard cabinets, making age alone a poor indicator of refacing viability. Focus on current structural condition rather than installation date when evaluating refacing potential.

Will refaced cabinets look as good as brand new cabinets to buyers or guests?

High-quality professional refacing with premium materials produces results virtually indistinguishable from new cabinets for all visible surfaces. New doors, drawer fronts, and professionally applied veneer on cabinet exteriors provide completely fresh appearances matching new construction quality. Most buyers and guests cannot differentiate between quality refacing and replacement without close inspection.

However, certain elements may reveal refacing upon detailed examination: cabinet interiors retain original finishes unless separately painted (adding $300-$900), cabinet box depth and height remain unchanged from original construction (modern cabinets often use deeper boxes), and cabinet layout and configuration cannot change without replacement. For typical use and visual assessment, well-executed refacing delivers aesthetic results equivalent to new cabinets at 40-55% lower cost. The primary visible difference isn’t quality but rather limitations in changing cabinet dimensions or configurations that replacement enables.

How long does cabinet refacing last before needing replacement or updating?

Professional cabinet refacing using quality materials typically lasts 15-20 years with proper care and maintenance, with some installations exceeding 25 years when cabinet boxes are exceptionally well-constructed. Longevity depends primarily on the underlying cabinet box condition and material quality rather than the refacing materials themselves, which often outlast the homeowner’s tenure in the property.

Material quality significantly impacts lifespan: laminate/thermofoil refacing lasts 10-15 years before showing edge peeling or surface wear, wood veneer refacing lasts 15-20 years with superior moisture resistance, and solid wood doors last 20-30+ years and can be refinished if desired. For comparison, budget stock replacement cabinets last 12-18 years, semi-custom cabinets last 20-28 years, and premium custom cabinets can exceed 30-50 years. The key to refacing longevity is selecting cabinets with solid plywood boxes in good structural condition—these provide the foundation supporting decades of additional service after professional refacing.

What hidden costs should I budget for beyond the quoted refacing or replacement price?

For refacing projects, budget an additional 10-15% beyond quoted prices for potential cabinet box repairs ($200-$1,200), hardware complications when changing hinge styles ($100-$400), interior painting to match new exteriors ($300-$900), and end panel or toe kick replacements not included in base quotes ($350-$1,000). Total hidden costs typically add $950-$3,500 to refacing quotes.

For replacement projects, budget 15-25% additional for countertop removal and reinstallation or replacement ($500-$8,000+), flooring repairs or replacement ($300-$6,000), electrical and plumbing adjustments ($500-$2,000), wall repair and painting ($500-$1,500), appliance modification panels ($200-$800), permit fees ($200-$800), disposal costs ($300-$600), and temporary kitchen setup expenses ($500-$2,000). Total hidden costs typically add $2,500-$21,700 to replacement quotes depending on project scope.

Both options may incur unexpected structural repairs discovered after work begins ($300-$1,500), change orders for scope modifications (10-20% of base cost), and post-completion touch-ups requiring additional visits. Always maintain 15-20% contingency funds for projects of either type to avoid budget stress when unexpected costs arise. The most commonly overlooked expenses are temporary living costs during extended projects and the opportunity cost of personal time invested in planning, material selection, and project management.

Final Reminder: This article contains affiliate links to products and services we recommend. Purchases made through these links may earn us a commission at no additional cost to you. We appreciate your support, which helps us continue providing comprehensive, unbiased content to help you make informed decisions about your home improvement projects.